What kind of equipment is used for fine crushed stone

Time:17 September 2025

Fine crushed stone is a crucial component in various construction and landscaping projects. The production of fine crushed stone involves several types of equipment designed to achieve specific sizes and qualities. This article provides a comprehensive overview of the equipment used in the process.

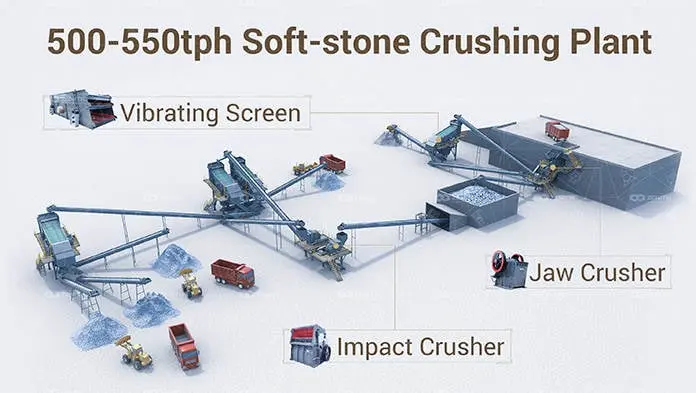

Crushing Equipment

Crushing equipment is essential in breaking down large stones into smaller, finer pieces. The following are the primary types of crushing equipment used:

Jaw Crushers

- Function: Jaw crushers are used for the initial stage of crushing large stones.

- Mechanism: They operate by compressing the stone between a fixed and a moving jaw.

- Advantages:

– High efficiency in breaking large stones

– Versatile for different stone types

Cone Crushers

- Function: Cone crushers are used for secondary crushing to produce finer stone.

- Mechanism: They crush stones by squeezing them between a gyrating spindle and an enclosing concave hopper.

- Advantages:

– Produces uniform fine stone

– Suitable for medium to hard stones

Impact Crushers

- Function: Impact crushers are used for tertiary crushing and refining stone size.

- Mechanism: They use impact force to break stones by throwing them against hard surfaces.

- Advantages:

– High reduction ratio

– Effective for softer stones

Screening Equipment

Screening equipment is used to separate crushed stone into different size categories. This ensures that the final product meets specific requirements.

Vibrating Screens

- Function: Vibrating screens sort crushed stone by size through vibration.

- Mechanism: They use a vibrating mechanism to move stone across a screen with various mesh sizes.

- Advantages:

– Precise sizing

– High throughput

Trommel Screens

- Function: Trommel screens are used for finer sorting of crushed stone.

- Mechanism: They rotate a cylindrical drum with screens to separate stone by size.

- Advantages:

– Effective for fine materials

– Reduces clogging

Conveying Equipment

Conveying equipment is essential for transporting crushed stone between different stages of processing.

Belt Conveyors

- Function: Belt conveyors move stone from crushers to screens and storage areas.

- Mechanism: They use a continuous belt looped around pulleys to transport stone.

- Advantages:

– Efficient transportation

– Adaptable to various layouts

Screw Conveyors

- Function: Screw conveyors are used for moving fine crushed stone.

- Mechanism: They use a rotating helical screw inside a tube to push stone forward.

- Advantages:

– Suitable for fine materials

– Compact design

Washing Equipment

Washing equipment is used to clean crushed stone and remove impurities.

Sand Washers

- Function: Sand washers clean fine crushed stone by removing dust and impurities.

- Mechanism: They use water and agitation to wash stone.

- Advantages:

– Produces cleaner stone

– Enhances quality

Hydrocyclones

- Function: Hydrocyclones separate particles based on size and density.

- Mechanism: They use centrifugal force to classify stone particles.

- Advantages:

– Efficient separation

– Compact and easy to integrate

Conclusion

The production of fine crushed stone involves a variety of equipment, each serving a specific purpose in the crushing, screening, conveying, and washing processes. Understanding the function and advantages of each type of equipment is crucial for optimizing production and ensuring the quality of the final product. By employing the right combination of equipment, producers can achieve the desired stone size and quality for various applications.