What type of crusher produces the least amount of fines

Time:18 September 2025

Crushers are essential equipment in the mining and aggregate industries, used to reduce the size of materials for further processing. One critical consideration when selecting a crusher is the amount of fines produced during the crushing process. Fines are small particles that can affect the quality and usability of the final product. This article explores the types of crushers that produce the least amount of fines and discusses their applications and benefits.

Types of Crushers

Several types of crushers are commonly used in the industry, each with its unique mechanism and suitability for different materials. The main types include:

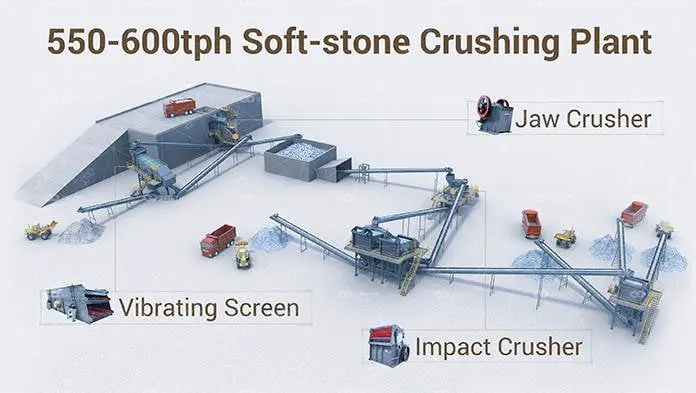

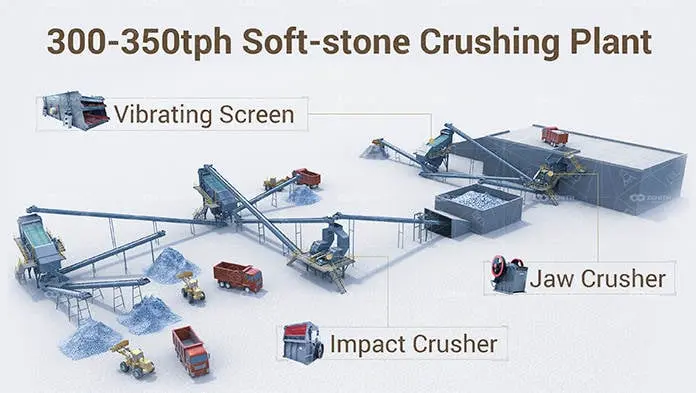

- Jaw Crushers

- Cone Crushers

- Impact Crushers

- Gyratory Crushers

- Roll Crushers

Crushers Producing the Least Amount of Fines

Among the various types of crushers, certain designs are more effective at minimizing the production of fines. These include:

Roll Crushers

Roll crushers are known for producing minimal fines. They consist of two rotating cylinders that crush materials between them. The main advantages include:

- Low Fines Production: The crushing mechanism of roll crushers is gentle, reducing the amount of fines produced.

- Uniform Product Size: Roll crushers provide consistent product size with minimal fines, ideal for applications requiring specific size distributions.

Jaw Crushers

Jaw crushers can also produce relatively low amounts of fines, particularly when used for primary crushing. Their characteristics include:

- Compression Crushing: Jaw crushers use compression to crush materials, which tends to produce fewer fines compared to impact crushing.

- Adjustable Settings: The gap setting between the jaws can be adjusted to control the size of the output and reduce fines.

Factors Affecting Fines Production

Several factors influence the amount of fines produced by crushers:

- Material Characteristics

– Hardness: Softer materials tend to produce more fines.

– Moisture Content: High moisture can lead to increased fines.

- Crusher Design

– Crushing Mechanism: Compression crushers typically produce fewer fines than impact crushers.

– Speed and Settings: The speed and settings of the crusher can be adjusted to minimize fines.

- Operational Parameters

– Feed Size: Larger feed sizes can reduce the production of fines.

– Throughput Rate: Optimizing the throughput rate can help control fines production.

Benefits of Reducing Fines

Minimizing the production of fines offers several advantages:

- Improved Product Quality: Reducing fines enhances the quality and consistency of the final product.

- Increased Efficiency: Less fines mean less waste and more efficient processing.

- Cost Savings: Lower fines production can reduce the need for additional processing and handling, saving costs.

Conclusion

Choosing the right type of crusher is crucial for minimizing the production of fines. Roll crushers and jaw crushers are generally preferred for applications where low fines production is desired. By understanding the factors that affect fines production and selecting the appropriate crusher, industries can improve product quality, increase efficiency, and achieve cost savings.