కాపర్ను తవ్వడానికి ఉపయోగించే యాంత్రిక పరికరాలు ఏమిటి?

సమయం:12 సెప్టెంబర్ 2025

Copper mining is a complex process that involves several stages, each requiring specialized mechanical equipment. This article explores the various types of machinery used in the copper mining industry, highlighting their roles and functionalities.

1. Exploration and Drilling

Before copper mining can commence, it is essential to locate and evaluate potential copper deposits. This stage involves:

- Drilling Rigs: Used to extract core samples from beneath the earth’s surface to assess the mineral content.

- Geophysical Equipment: Tools such as magnetometers and gravimeters help in mapping the subsurface geology.

2. Extraction

Once a viable copper deposit is identified, the extraction process begins. This involves:

2.1 Open-Pit Mining

Open-pit mining is the most common method for extracting copper. The equipment used includes:

- Excavators: Large machines used to remove overburden and ore from the mine.

- Dump Trucks: Transport the extracted ore and waste material to processing plants or waste dumps.

- Drilling and Blasting Equipment: Used to break up the rock to make it easier to transport and process.

2.2 Underground Mining

For deeper deposits, underground mining is employed. Key equipment includes:

- Loaders: Also known as LHD (Load, Haul, Dump) machines, these are used to load ore into trucks or onto conveyors.

- Mine Trucks: Transport ore from the mining face to the surface.

- Jumbo Drills: Used for drilling holes in which explosives are placed for blasting.

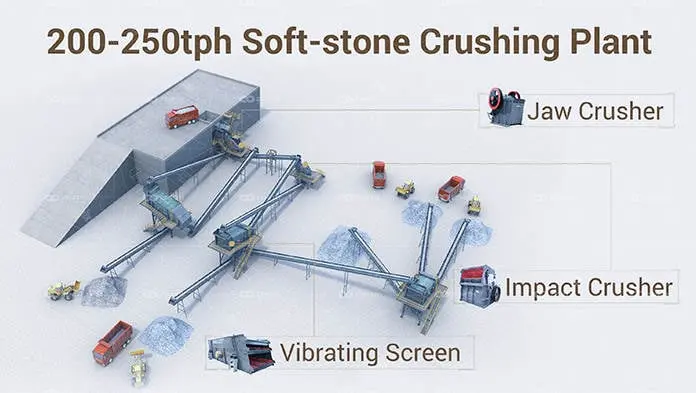

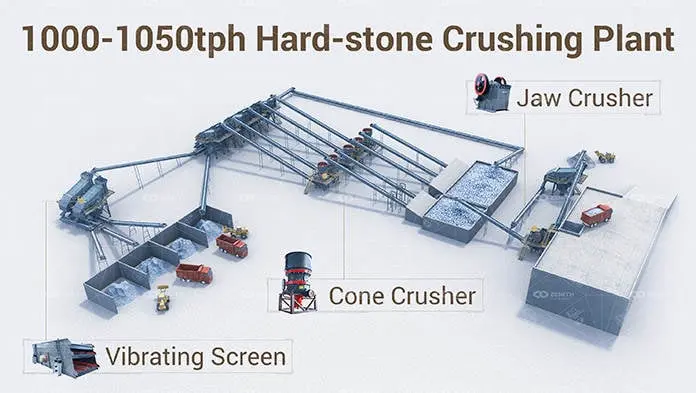

3. Crushing and Grinding

After extraction, the copper ore must be crushed and ground to liberate the copper minerals. Equipment used in this stage includes:

- Jaw Crushers: Break down large chunks of ore into smaller pieces.

- Cone Crushers: Further reduce the size of the ore particles.

- Ball Mills: Grind the crushed ore into a fine powder, facilitating the separation of copper from other minerals.

4. Concentration

The concentration process separates copper minerals from waste rock. Equipment used includes:

- Froth Flotation Cells: Utilize chemicals and air bubbles to separate copper minerals from the slurry.

- Thickeners: Concentrate the copper slurry by removing excess water.

- Filters: Remove additional moisture from the copper concentrate.

5. ఉక్కు నూనె మరియు శుద్ధీకరణ

The final stage in copper production involves smelting and refining the concentrate to produce pure copper. Key equipment includes:

- Smelters: Furnaces that heat the concentrate to high temperatures, separating copper from impurities.

- Electrolytic Cells: Used in the refining process to achieve high-purity copper through electrolysis.

- Anode Furnaces: Further refine the copper to remove any remaining impurities.

6. Ancillary Equipment

In addition to the primary machinery, several ancillary tools and equipment support the copper mining process:

- Conveyors: Transport ore and waste materials within the mine and processing facilities.

- Pumps: Move water and slurry throughout the mining and processing operations.

- Ventilation Systems: Ensure adequate airflow in underground mines to maintain safe working conditions.

తీర్మానం

Copper mining is a multifaceted operation that relies heavily on specialized mechanical equipment. From exploration to refining, each stage of the process requires specific machinery to efficiently and safely extract and process copper ore. Understanding the role of each piece of equipment is crucial for optimizing the mining process and ensuring the sustainable production of copper.