What plant and equipment are required for a coal extraction project

Time:12 September 2025

Coal extraction is a complex process that involves various stages and requires a range of specialized plant and equipment. This article provides a detailed overview of the essential machinery and tools needed for a successful coal extraction project.

1. Exploration and Surveying Equipment

Before mining operations can commence, thorough exploration and surveying are necessary to assess the coal deposit.

- Geophysical Instruments: Used for seismic surveys to understand the geological structure.

- Drilling Rigs: For core sampling to determine the quality and quantity of coal.

- GPS and GIS Systems: For accurate mapping and planning of the mining site.

2. Site Preparation Equipment

Once a site is selected, preparation is crucial to ensure safe and efficient operations.

- Bulldozers: For clearing vegetation and leveling the ground.

- Excavators: Used for digging and removing overburden (the soil and rock overlaying the coal seam).

- Grading Equipment: To create stable surfaces for roads and infrastructure.

3. Extraction Equipment

The core of any coal extraction project is the equipment used to remove the coal from the earth.

3.1 Surface Mining Equipment

For open-pit or strip mining, the following equipment is essential:

- Draglines: Large machines used to remove overburden and expose coal seams.

- Bucket Wheel Excavators: For continuous digging and removal of material.

- Shovels and Loaders: For loading coal onto transport vehicles.

3.2 Underground Mining Equipment

For underground mining operations, specialized machinery is required:

- Continuous Miners: Machines that cut and gather coal without drilling and blasting.

- Longwall Miners: Used in longwall mining to shear coal from the face.

- Roof Bolters: To secure the roof of the mine and ensure safety.

4. Transportation Equipment

Efficient transportation systems are vital to move coal from the extraction site to processing facilities.

- Conveyor Belts: For transporting coal over short distances within the mine.

- Trucks and Haulage Vehicles: For moving coal to processing plants or railheads.

- Rail Systems: For long-distance transport of coal to end users or ports.

5. Processing Equipment

Once extracted, coal must be processed to meet market specifications.

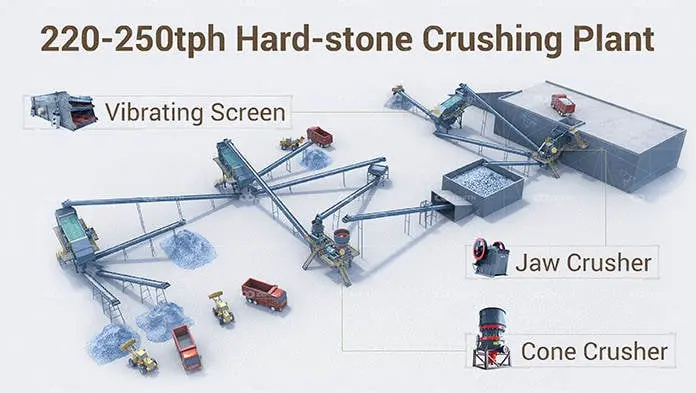

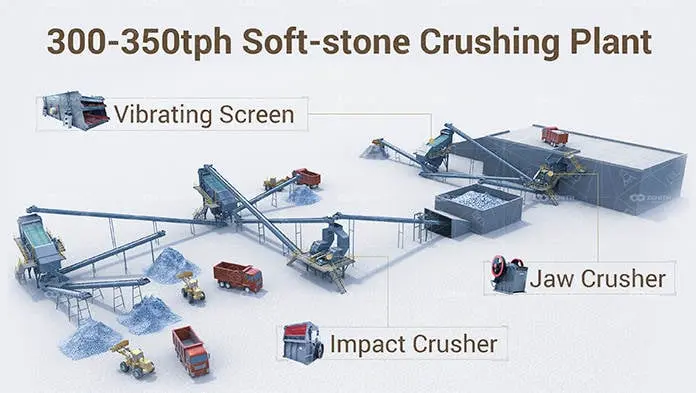

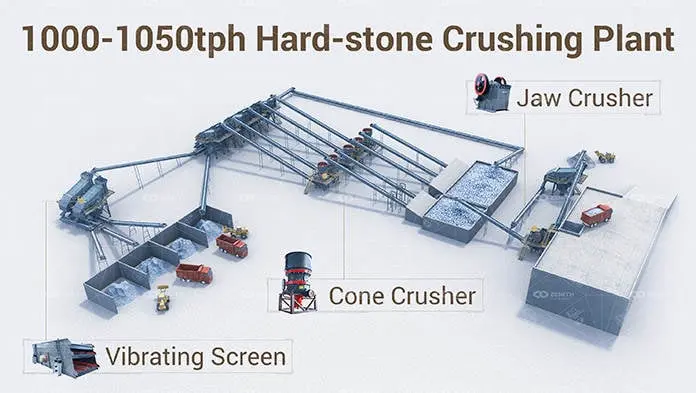

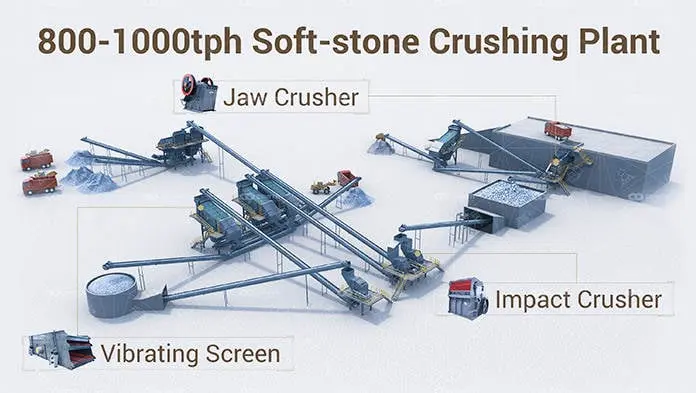

- Crushers: To reduce the size of coal for easier handling and processing.

- Screens: For sorting coal by size and removing impurities.

- Wash Plants: To clean coal and improve its quality by removing soil and rock.

6. Safety and Environmental Equipment

Ensuring the safety of workers and minimizing environmental impact are critical components of a coal extraction project.

- Ventilation Systems: To provide fresh air and remove hazardous gases in underground mines.

- Dust Suppression Systems: To control dust generated during mining and processing.

- Water Treatment Plants: For managing and treating wastewater from mining operations.

7. Support and Maintenance Equipment

Regular maintenance and support are necessary to keep the plant and equipment operational.

- Workshops and Toolkits: For on-site repairs and maintenance.

- Mobile Cranes: For lifting and moving heavy equipment during maintenance.

- Fuel and Lubrication Systems: To ensure machinery operates smoothly and efficiently.

Conclusion

A coal extraction project requires a diverse array of plant and equipment, each serving a specific purpose in the mining process. From exploration and site preparation to extraction, transportation, and processing, the right machinery is essential for efficient and safe operations. Additionally, safety and environmental considerations must be integrated into every aspect of the project to ensure sustainable mining practices.