Although some gold is obtained by the amalgamation or flotation! Of gravity concentrates, cyanidation is the essential process for the extraction of gold. When concentration is introduced, it isolates a portion of the ore that is enriched in gold or that contains refractory gold, so that that portion can be subjected to fine grinding before cyanidation. Other operations that may increase the dissolution of gold by cyanidation are prior acid leaching for uranium-rich material, or roasting for sulphides or carbonaceous constituents. The benefits of concentration are that it confines the intensive treatment to the concentrate and makes possible a reduction of the loss of soluble gold. This loss is a function of the amount of gold in the pregnant solution; cyanidation of the tailing from the concentration process leads to little loss of soluble gold because of the small amount of gold that has to be recovered from the tailing, while the treatment of a small amount of concentrate justifies special precautions to minimize the soluble loss.

Because the gold in Witwatersrand ores is associated with pyrite and uranium minerals, the concentration of gold is generally accompanied by the concentration of uranium, and often also by the concentration of pyrite; frequently the recoveries of gold and uranium are closely related. A noteworthy effect of the simultaneous recovery of several valuable constituents is that the economic benefit of the concentration process must be assessed with regard to all the valuable constituents, not merely to the gold; in fact, in the concentration of cyanidation residues, the value of the gold in the concentrate is frequently less than that of the uranium, and in some instances recovery of the gold would not be justified if uranium and/or pyrite did not contribute to the value of the concentrate. The research and development programme of the National Institute for Metallurgy (NIM) on the treatment of Witwatersrand ores and residues has therefore been carried out in collaboration with the Extraction Metallurgy Division of the Atomic Energy Board (AEB), which is responsible for all the work undertaken by the State on the concentration and recovery of uranium.

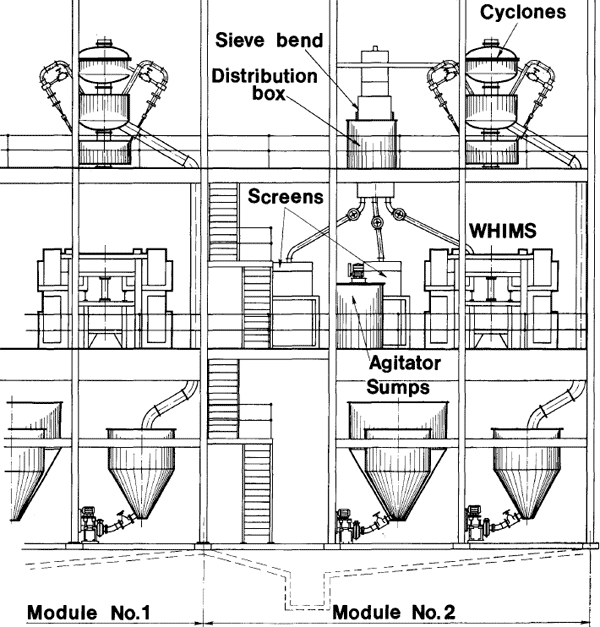

Introduction of Wet High-intensity Magnetic Separation

Many concentration processes have been applied to Witwatersrand ores at various times. They include gravity concentration by jigs, shaking tables, various surface-film concentrators, and heavy media; flotation; sorting by manuals, radiometric, and optical means; and selective crushing and screening. To these processes must now be added wet high-intensity magnetic separation (WHIMS).

The first published reference to the use of this process for Witwatersrand ores was made in 1975 in a short paper from NIM describing the process and some of its possible applications. Since then NIM, AEB, and the gold uranium industry have learnt much about the process; this paper reviews the work undertaken by NIM and AEB on its application to gold-uranium ores and cyanidation residues.

That uranium and gold could be concentrated by high intensity magnetic separation was first observed during the centralized research programme on the extraction of uranium that was initiated at the Government Metallurgical Laboratory in 1946. No importance was attached to the observation because, at that time, high-intensity magnetic separation meant a dry process, which was not practicable for Witwatersrand ores. The advent of wet high-intensity separators revived NIM’s interest in magnetic separation, and a small batch-type separator (Eriez model HIW4L) was purchased in 1967, and this enabled exploratory tests to be done on many ores and residues. A laboratory-model continuous separator (Carpco model MWL3) was acquired in 1970, and a pilot-plant machine suitable for on-site testing at the mines (Eriez model CF-30) was purchased in 1975. All these machines were used with a matrix of iron balls. Early experiments indicated that, although WHIMS was potentially an efficient method of concentration, it would require a considerable amount of investigation before it could be applied in practice. Therefore, the work of NIM and AEB had to be extended, and the following aspects were dealt with as interrelated investigations.

- (1) Preliminary tests on ores and residues in the batch separator to obtain approximate indications of their response to WHIMS and to identify those that merited further investigation.

- (2) Tests on batch and continuous separators to determine the effect of the various operating conditions.

- (3) Tests on continuous separators to obtain more reliable indications of metallurgical results than are possible from batch tests.

- (4) On-site pilot-plant experiments to disclose and overcome operating difficulties and to estimate capacities of large machines.

- (5) Development of a modified separator to overcome the problems resulting from the presence of ferromagnetic particles and wood chips.

- (6) Development of a flow sheet for gold and uranium extraction based on a coarse grind, gravity concentration, and WHIMS.

- (7) Mineralogical examinations of the products of concentration.

- (8) Leaching tests to determine the extractions of gold and uranium that can be obtained from WHIMS concentrates.

- (9) An analysis of the separation process in a continuous separator as an aid to the design and operation of WHIMS machines.

- (10) Assessment of the cost of WHIMS.

Small-scale Batch Tests

Numerous ores and cyanidation residues were tested in the Eriez batch separator. However, in order to facilitate the testwork, to make the tests more reproducible, and to enable the flow-rate through the separator to be controlled, the separator was modified by the addition of feed and discharge facilities. An adverse effect of the modification is that, under the conditions used for most of the tests, results were obtained that were considerably better than can be expected from most continuous machines. This is attributed mainly to the fact that in most continuous machines there is little control of the flow-rate through the separating zone, whereas the modified batch machine can be operated at controlled average flow-rates that are lower than those obtainable in practice.

Some of the results obtained in the tests with the modified batch separator are shown in Table I. Despite the fact that many of the results are more favourable than are expected from most currently available WHIMS separators, the table is of interest because it indicates that WHIMS can effect considerable recoveries of gold and uranium from most residues, distinguishes between residues that merit further examination and those that are unpromising, and provides a level of performance that can reasonably be aimed at in the design of improved separators.

It will be observed that there is a fairly good correlation between the recoveries of gold and those of uranium, and that tailings from the flotation for the recovery of gold, pyrite, and uranium (described in the table only as ‘flotation tailings’) yield additional recoveries of gold and uranium. Also noteworthy are the amounts of gold and uranium recoverable from cyanidation residues that have been acid-leached to extract the uranium.