Jaw crusher can be divided into two according to the amplitude of motion of the moving face. The different types of Jaw Crushers are:

Blake Type Jaw Crusher

In this the movable jaw is hinged at the top of the crusher frame so that the maximum amplitude is obtained at the bottom of the crushing jaws. Blake Crushers are operated by toggles and controlled by a pitman. These are commonly used as primary crushers in the mineral industry. The size of the feed opening is referred to as the gape. The opening at the discharge end of the jaws is referred to as the set. The Blake crushers are single or double toggle drives. The function of the toggle(s) is to move the pivoted jaw. The retrieving action of the jaw from its furthest end of travel is by springs for small crushers or by a pitman for larger crushers. As the reciprocating action removes the moving jaw away from the fixed jaw the broken rock particles slip down, but are again caught at the next movement of the swinging jaw and crushed. This process is repeated until the particle sizes are smaller than the smallest opening between the crusher plates at the bottom of the crusher (the closed set).

For a smooth reciprocating action of the moving jaws, heavy flywheels are used in both types of crushers. Blake type jaw crusher may be divided into two types.

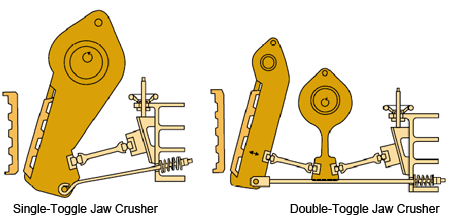

(a) Single toggle type: – In this the number of toggle plate is only one. It is cheaper and has less weight compare to a double toggle type jaw crusher. The function of the toggle(s) is to move the pivoted jaw.

(b) Double toggle type: – Here the number of toggle plate is two. Over the years many mines have used the double-toggle style of crusher because of its ability to crush materials, including mineral bearing ores that were both tough and abrasive. While many aggregate producers have used the overhead eccentric style. There are many factors that should be considered when deciding which style would be best for your application.

For larger material crushing, always larger Blake type jaw crushers are selected. The characteristics of this type of crusher are as following

- 1. Larger, rough, blocky as well as sticky rock or ore lumps can be crushed.

- 2. Reinforcement of the crusher is possible with the help of high strength crusher frame to crush very hard rock or ore lumps.

- 3. It is very simple to adjust to prevent much of wear and also very easy to repair,

- 4. Maintenance o the crusher is very easy.

Dodge Type Jaw Crusher

The moving plate is pivoted at the bottom and connected to an eccentric shaft. In universal crushers the plates are pivoted in the middle so that both the top and the bottom ends can move. The movable jaw is hinged at the bottom of the crusher frame so that the maximum amplitude of motion is obtained at the top of the crushing jaws. They are comparatively lower in capacity than the Blake crushers and are more commonly used in laboratories.