What equipment is typically used in iron ore crushing processes

Time:19 September 2025

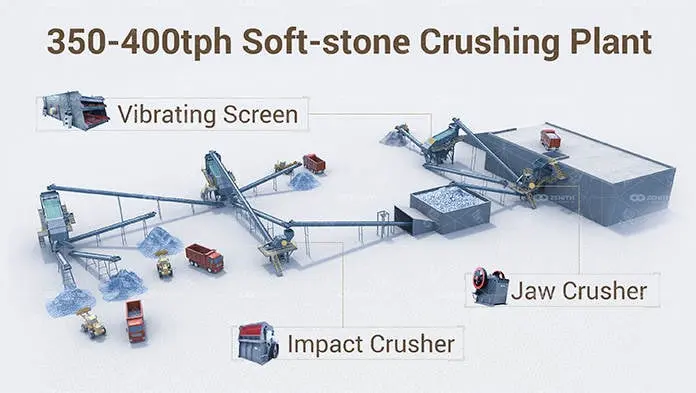

Iron ore crushing is a critical process in the mining industry, where raw iron ore is transformed into smaller, manageable pieces for further processing. This article explores the various types of equipment typically used in iron ore crushing processes.

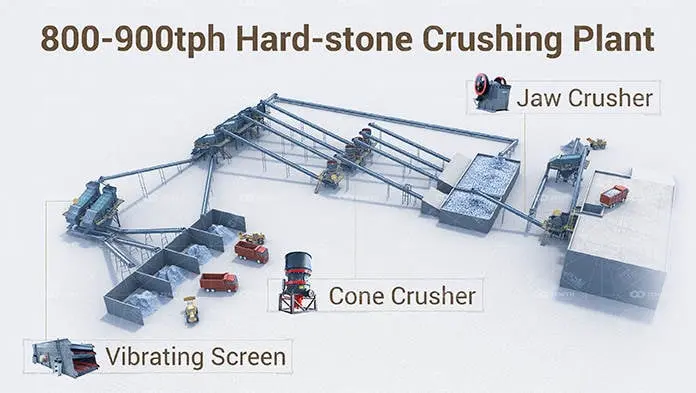

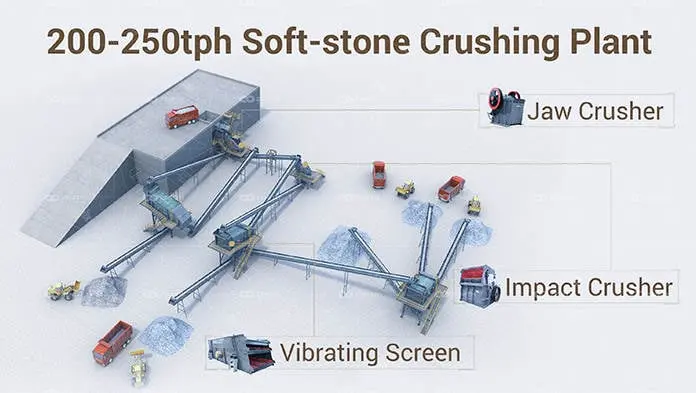

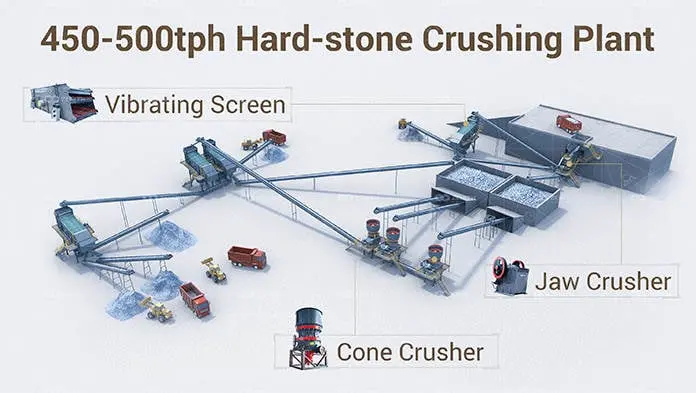

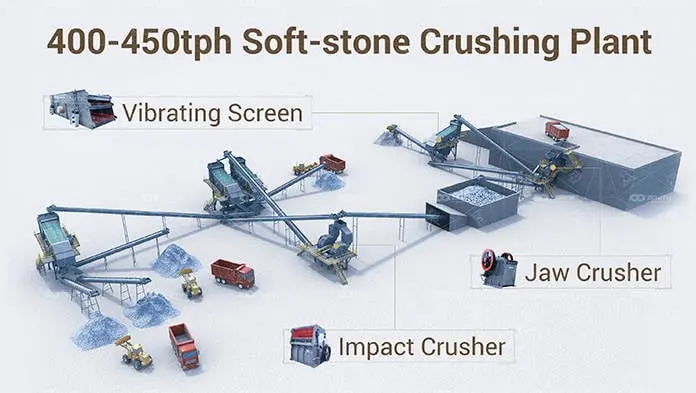

Primary Crushing Equipment

Primary crushing is the first stage in the iron ore crushing process. It involves reducing large chunks of raw iron ore into smaller pieces.

Jaw Crushers

- Function: Jaw crushers are used to crush large pieces of iron ore into smaller sizes.

- Design: They consist of two plates, one stationary and one moving, which crush the ore by compressive force.

- Advantages:

– High capacity

– Simple structure

– Reliable operation

Gyratory Crushers

- Function: Gyratory crushers are used for primary crushing of iron ore.

- Design: They have a conical shape and a gyrating spindle, which crushes the ore against the chamber walls.

- Advantages:

– High throughput

– Suitable for hard and abrasive materials

Secondary Crushing Equipment

Secondary crushing further reduces the size of iron ore after primary crushing.

Cone Crushers

- Function: Cone crushers are used to crush iron ore into smaller, uniform sizes.

- Design: They have a rotating cone within a fixed chamber, which crushes the ore by squeezing it.

- Advantages:

– High efficiency

– Consistent product size

– Low operational costs

Impact Crushers

- Function: Impact crushers use impact force to crush iron ore.

- Design: They have a rotor with hammers that strike the ore, breaking it into smaller pieces.

- Advantages:

– High reduction ratio

– Ability to handle wet materials

Tertiary Crushing Equipment

Tertiary crushing is the final stage of crushing, producing fine particles suitable for further processing.

Vertical Shaft Impact (VSI) Crushers

- Function: VSI crushers are used for producing finely crushed iron ore.

- Design: They use a high-speed rotor to throw ore against a hard surface, breaking it into fine particles.

- Advantages:

– Produces high-quality aggregates

– Adjustable product size

High-Pressure Grinding Rolls (HPGR)

- Function: HPGR are used for tertiary crushing and grinding of iron ore.

- Design: They consist of two rotating rolls that apply high pressure to crush and grind the ore.

- Advantages:

– Energy-efficient

– Produces fine particles with less over-grinding

Supporting Equipment

Supporting equipment plays a vital role in ensuring the efficiency and effectiveness of the crushing process.

Feeders

- Function: Feeders regulate the flow of iron ore into crushers.

- Types:

- Vibrating Feeders: Use vibration to move ore into the crusher.

- Apron Feeders: Use a series of metal plates to transport ore.

Screens

- Function: Screens separate crushed iron ore into different size fractions.

- Types:

- Vibrating Screens: Use vibrating motion to sort ore.

- Rotary Screens: Use rotating drums to separate ore.

Conveyors

- Function: Conveyors transport crushed iron ore between different stages of the crushing process.

- Types:

- Belt Conveyors: Use a continuous belt to move ore.

- Roller Conveyors: Use rollers to transport ore.

Conclusion

The iron ore crushing process involves several stages, each requiring specific equipment to achieve optimal results. From primary crushers like jaw and gyratory crushers to tertiary equipment like VSI crushers and HPGR, each piece of machinery plays a crucial role in transforming raw iron ore into usable material. Supporting equipment such as feeders, screens, and conveyors ensure the smooth operation of the crushing process, contributing to the efficiency and productivity of iron ore mining operations.