What machines are used in mines

Time:12 September 2025

Mining is a complex industry that involves the extraction of minerals and other geological materials from the earth. To achieve this, a variety of machines are employed to ensure efficiency, safety, and productivity. This article explores the different types of machines used in mining operations.

1. Drilling Machines

Drilling machines are essential for creating holes in the earth’s surface to access mineral deposits.

- Rotary Drills: Used for creating large holes for blasting operations.

- Percussion Drills: Utilize a hammering action to break rock.

- Diamond Drills: Employ a diamond-tipped bit for precision drilling in hard rock.

2. Excavation Equipment

Excavation equipment is used to remove overburden and extract minerals.

- Excavators: Versatile machines used for digging and moving large amounts of earth.

- Draglines: Large machines with a long boom used for surface mining.

- Bucket Wheel Excavators: Massive machines used in open-pit mining to remove overburden.

3. Loading and Hauling Equipment

Once minerals are extracted, they need to be transported for processing.

- Loaders: Machines like front-end loaders are used to load materials onto trucks.

- Haul Trucks: Large trucks designed to transport heavy loads of mined material.

- Conveyor Belts: Used for continuous transport of materials over long distances.

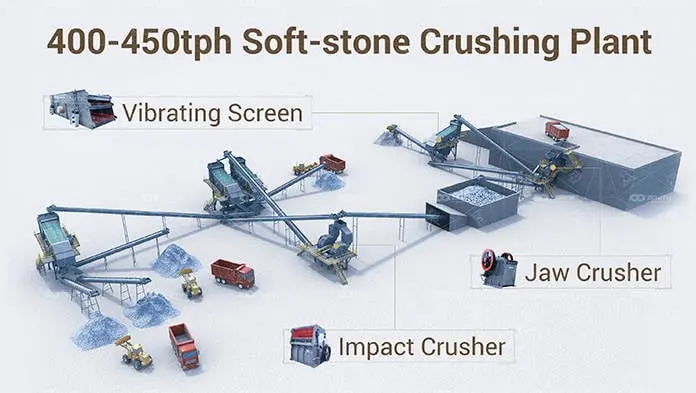

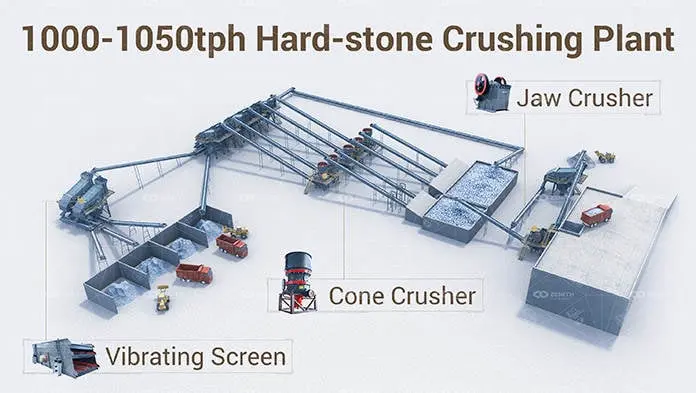

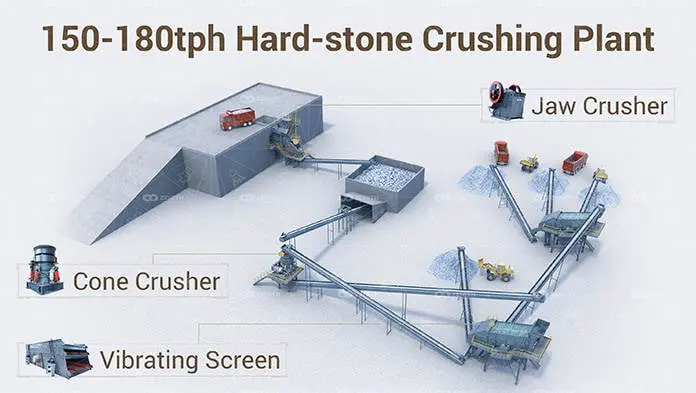

4. Crushing and Grinding Machinery

These machines are used to break down mined materials into smaller, more manageable pieces.

- Jaw Crushers: Used for primary crushing of large rocks.

- Cone Crushers: Secondary crushers that further reduce rock size.

- Ball Mills: Grind materials into fine powder for further processing.

5. Screening Equipment

Screening machines separate materials based on size.

- Vibrating Screens: Use vibration to separate materials into different sizes.

- Trommel Screens: Rotating drums that screen materials by size.

6. Underground Mining Equipment

Specialized machines are required for underground mining operations.

- Continuous Miners: Machines that cut and gather material as they move forward.

- Longwall Miners: Used for extracting coal in long, horizontal sections.

- Shuttle Cars: Transport material from the mining face to the conveyor system.

7. Support and Maintenance Equipment

Ensuring the safety and efficiency of mining operations requires additional machinery.

- Roof Bolters: Machines that install bolts to support mine roofs.

- Maintenance Vehicles: Specialized vehicles equipped with tools for on-site repairs.

- Ventilation Systems: Essential for providing fresh air and removing hazardous gases.

8. Safety Equipment

Safety is a top priority in mining, and various machines help protect workers.

- Gas Detection Systems: Monitor air quality and detect hazardous gases.

- Emergency Rescue Vehicles: Equipped for rapid response in case of accidents.

- Personal Protective Equipment (PPE): Includes helmets, gloves, and respirators.

Conclusion

Mining operations rely on a diverse range of machines to perform tasks efficiently and safely. From drilling and excavation to transportation and safety, each machine plays a crucial role in the mining process. Understanding the functions and capabilities of these machines is essential for anyone involved in the mining industry.