Gulin® is a famous coal washing machine manufacturer in China, and offer coal washery, coal crusher, grinding, mill, screen, washing machine like jigger, Shaking tables, cylindrical separators, spiral classifier, flotation unit for coal washing plant in India, Russia, Canada, Vietnam, Indonesia, Australia China, USA, Germany, South Africa, Poland, Zimbabwe, Columbia, Pakistan, Philippines.

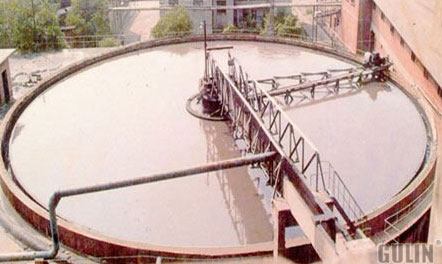

Coal Washing Machine

Coal Washing Machine

Coal washing machine reduces the ash content of coal by over 50%, resulting in less waste. About 25% of the sulfur content is reduced, lowering the amount of sulfur dioxide emissions released upon combustion.

Coal washing plant also improves the heating value of coal, known as the thermal efficiency, which reduces carbon dioxide emissions as well.

Coal washing processing flow process

Coal washing is the process of removal of the contaminants and the lower grade coal to achieve a product quality which is suitable to the application of the end user – either as an energy source or as a chemical agent or feedstock. A common term for this process is coal beneficiation or “cleaning”.

Coal beneficiation largely depends on gravity difference of coal and ash particle.

Coal Washing – There are two coal cleaning processes that predominate in the industry: dense medium (DM) separation and JIG washing. JIG washing, which is a water-based process that relies on the pulsation of water through the particle bed to stratify particles of different density, is widely perceived as a simpler, lower-cost option than DM separation.

Coal is first ground into smaller pieces so that it can be more easily processed. The pulverized coal is then washed in water or in fluids with densities that cause the coal to float so that unwanted impurities can sink to the bottom.

Coal washery process

Coal washery process has been used successfully within unsealed road pavements and for haul roads at many collieries. Coal washery plant has been used sparingly by the many cities in the China as a subbase material. Subbase coal washery process is typically stabilised with cement in India.

Other coal process machine

One of the oldest of these devices is the jig. In a jig, the column of water is maintained in a constant up-and-down movement by means of a flow of air. Clean coal particles are carried to the top of the jig by this motion, while heavier refuse particles sink to the bottom.

Another method of extraction, the cyclone, consists of a tank in which the working fluid (water or a heavy medium) is kept in a constant circular motion. The tank is constructed so that lighter clean coal particles are thrown out of one side, while heavier refuse particles are ejected through the bottom.

Shaking tables are another extraction method. As the table shakes back and forth, particles are separated by size, producing clean coal at one end and waste products at the other.

In cylindrical separators, a coal mixture is fed into a spinning column of air that throws the heavier waste particles outward. They coat the inner wall of the cylinder and fall to the bottom, where they are drawn off. The clean coal particles remain in the center of the air column and are drawn off at the top of the cylinder.