What is antimony?

Antimony is a silvery white metal of medium hardness that breaks easily. Antimony ores are mined and then either changed into antimony metal or combined with oxygen to form antimony oxide. It is a white powder that does not evaporate. Antimony is used in lead storage batteries, solder, sheet and pipe metal, bearings, castings, type metal, ammunition, and pewter.

Production process of Antimony

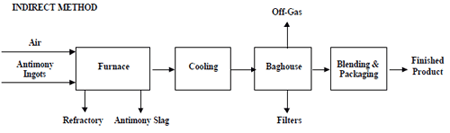

Antimony oxide can be prepared using one of two processes: the direct and the indirect, in this section, general descriptions of these two processes are provided. The process flow diagrams for these general production descriptions are presented in figure 2.1.

Antimony oxide production via the indirect method

In this process, antimony metal (sources include ingots, ore, and sodium antimonite) is melted in a furnace. The molten metal is burned producing an antimony oxide vapor. The vapors are quenched with air and then cooled in hairpin coolers. Antimony oxide sublimes directly from a vapor to a white powdery solid. A filtering method such as a baghouse. Is used to recover the antimony powder. The antimony oxide powder is then blended and packaged for shipment.

Antimony oxide production via the direct method

In this process, crude (low grade) antimony oxide is roasted in the presence of air to produce antimony oxide vapors. The vapors are condensed to generate antimony oxide powder. A baghouse is used to recover product in the off-gas. The antimony oxide powder is then blended classified and bagged for shipment. The crude antimony oxide comes either from off-site or is reclaimed from secondary materials from within the facility.

Antimony Ore Beneficiation Process Chart

Antimony ore dressing method, basically have hand picking, re-election, the flotation methods. One of them, looking at flotation of concentrator for further, followed by hand picking. A few antimony ore flotation process through the use of single concentrator, most antimony ore concentrator can adopt combination process, like the hand picking – flotation process, hand picking – re-election – flotation process.

| NO. | Equipment | NO. | Equipment | NO. | Equipment |

|---|---|---|---|---|---|

| 1 | tipping bin | 2 | jaw crusher with 100mm setting: The major crushing equipment for antimony ore primary crushing. | 3 | storage bin |

| 4 | endless rope haulage | 5 | grizzly | 6 | jaw crusher with 50mm setting: The jaw crushing equipment for antimony ore secondary crushing. |

| 7 | rod deck vibrating screen | 8 | gyratory crusher | 9 | antimony ore mill bins |

| 10 | ball mills: The major grinding equipment for antimony ore grinding. | 11 | corduroy tables | 12 | cyclones |

| 13 | thickeners | 14 | conditioners | 15 | 3-way pulp distributor |

| 16 | rougher cells | 17 | cleaner cells | 18 | tailings thickener |

| 19 | metering tanks | 20 | arsenic flotation cells | 21 | concentrating table |

| 22 | concentrate thickeners | 23 | filter | 24 | slimes dam |

| 25 | drying |