what are the steps limestone ore processed

Time:12 September 2025

Limestone is a sedimentary rock composed mainly of calcium carbonate (CaCO₃). It is a vital raw material in various industries, including construction, agriculture, and manufacturing. Processing limestone ore involves several steps, each crucial to obtaining the desired product quality. This article outlines the detailed steps involved in limestone ore processing.

Overview of Limestone Processing

Limestone processing involves transforming the raw limestone ore into usable products. The main steps include:

- Extraction

- Crushing and Screening

- Grinding

- Calcination

- Hydration (if producing hydrated lime)

- Packaging and Distribution

Step-by-Step Limestone Ore Processing

1. Extraction

The first step in limestone processing is the extraction of limestone ore from quarries. This involves:

- Surveying and Planning: Identifying and mapping limestone deposits.

- Drilling and Blasting: Using controlled explosives to break the limestone into manageable pieces.

- Loading and Hauling: Transporting the blasted limestone to the processing plant.

2. Crushing and Screening

Once extracted, the limestone ore undergoes crushing and screening to achieve the desired size and quality.

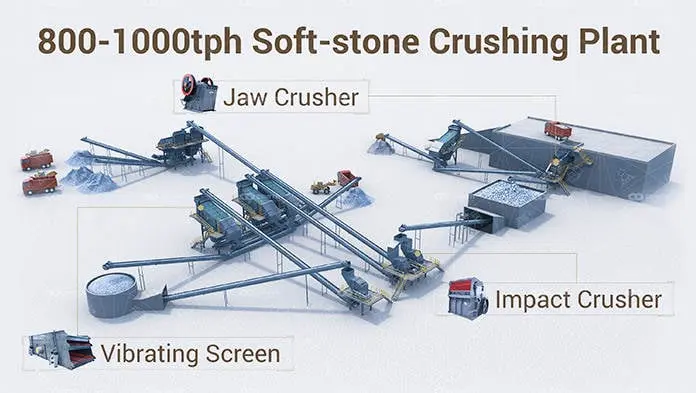

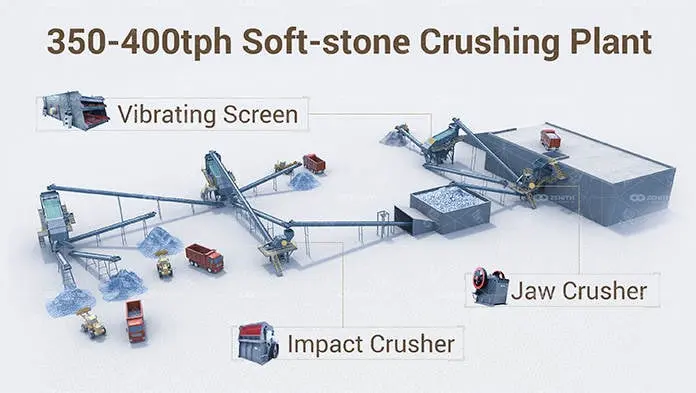

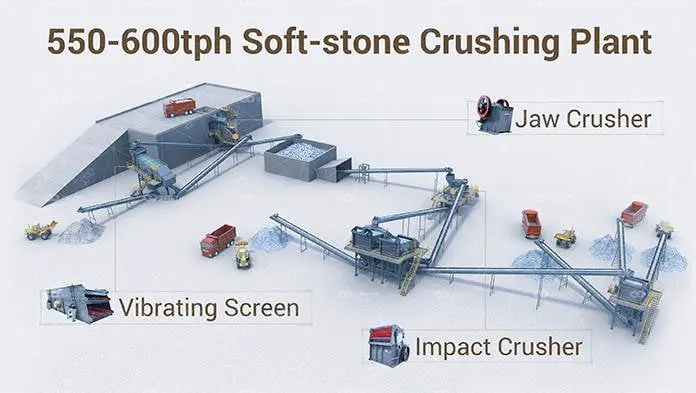

- Primary Crushing: Large chunks of limestone are fed into a crusher to reduce their size.

- Secondary Crushing: Further reduction of size using cone crushers or impact crushers.

- Screening: Separating crushed limestone into different size fractions using vibrating screens.

3. Grinding

Grinding is essential for producing fine limestone powder, which is required for various applications.

- Ball Mills or Roller Mills: Used to grind the limestone to a fine consistency.

- Classification: Separating fine particles from coarser ones using classifiers.

4. Calcination

Calcination is the process of heating limestone to high temperatures to produce lime (CaO).

- Kilns: Rotary kilns or shaft kilns are used for calcination.

- Temperature Control: Maintaining temperatures between 900°C and 1100°C for optimal calcination.

- Cooling: Rapid cooling of lime to stabilize its structure.

5. Hydration (Optional)

For producing hydrated lime, an additional step is required:

- Hydration: Mixing quicklime with water to produce hydrated lime (Ca(OH)₂).

- Slaking: Controlling the reaction to ensure complete hydration.

6. Packaging and Distribution

The final step involves packaging the processed limestone products for distribution.

- Bagging: Packaging lime products in bags or bulk containers.

- Quality Control: Ensuring product quality meets industry standards.

- Logistics: Organizing transportation to deliver products to customers.

Applications of Processed Limestone

Processed limestone is used in various applications, including:

- Construction: As aggregate in concrete and asphalt.

- Agriculture: As a soil conditioner and fertilizer.

- Manufacturing: In the production of glass, cement, and steel.

- Environmental: For water treatment and flue gas desulfurization.

Conclusion

Limestone ore processing is a multi-step procedure that transforms raw limestone into valuable products. Each step, from extraction to packaging, plays a crucial role in ensuring the quality and usability of the final product. Understanding these steps is essential for optimizing the processing of limestone and meeting industry demands.