What crusher is used by foundry for aluminum

Time:19 September 2025

Foundries play a crucial role in the manufacturing industry by producing metal castings. One of the common materials processed in foundries is aluminum. To efficiently handle and recycle aluminum scrap, foundries utilize crushers. This article explores the types of crushers used by foundries for aluminum, their features, and their benefits.

Overview of Aluminum Processing in Foundries

Aluminum is a lightweight, durable, and corrosion-resistant metal widely used in various industries. In foundries, aluminum scrap is melted and cast into new products. Before melting, aluminum scrap must be processed to ensure optimal size and purity. Crushers are essential in this preprocessing stage.

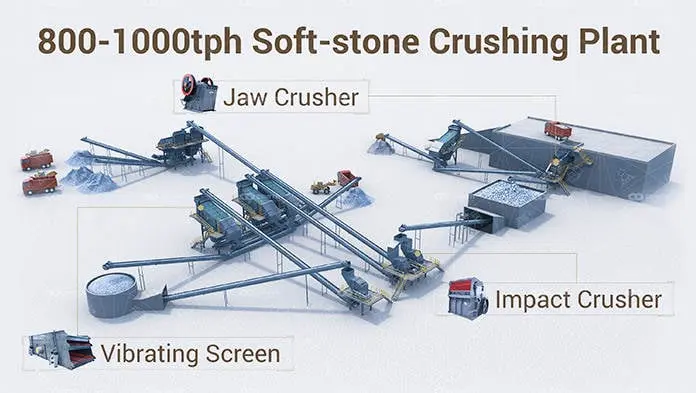

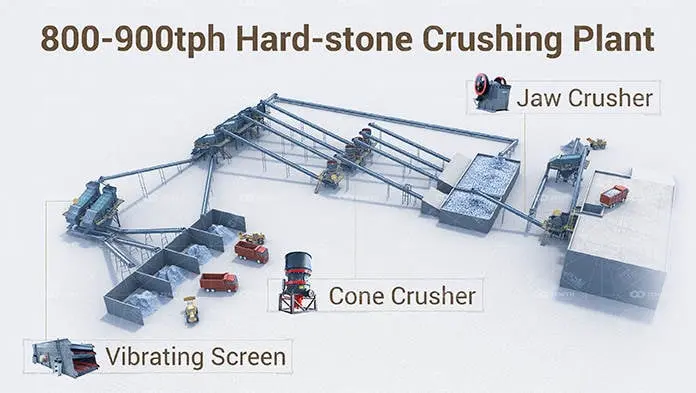

Types of Crushers Used for Aluminum

Foundries employ different types of crushers depending on their specific needs. The choice of crusher is influenced by factors such as the size of the aluminum scrap, desired output size, and production capacity.

1. Jaw Crushers

Jaw crushers are commonly used in foundries for aluminum processing due to their ability to handle large and bulky scrap. They operate by compressing material between a fixed jaw and a moving jaw.

– Suitable for large aluminum scrap

– Simple design and operation

– High throughput capacity

– Limited to primary crushing

– Not ideal for fine crushing

2. Impact Crushers

Impact crushers utilize impact force to break down aluminum scrap. They are ideal for processing medium-sized scrap and achieving finer output sizes.

– Capable of producing finer output

– Versatile for various scrap sizes

– High reduction ratio

– Wear and tear on impact surfaces

– Requires regular maintenance

3. Cone Crushers

Cone crushers are used for secondary crushing of aluminum scrap. They provide precise control over the output size and are suitable for producing uniform particles.

– High efficiency in secondary crushing

– Consistent output size

– Durable and reliable

– Complex design

– Higher operational costs

4. Hammer Mills

Hammer mills are versatile crushers that use rotating hammers to pulverize aluminum scrap. They are effective for both primary and secondary crushing.

– Suitable for a wide range of scrap sizes

– High-speed operation

– Can handle both hard and soft materials

– High energy consumption

– Potential for excessive dust generation

Factors Influencing Crusher Selection

Selecting the right crusher for aluminum processing involves considering several factors:

- Scrap Size: The initial size of the aluminum scrap determines the type of crusher needed.

- Desired Output: The required size and purity of the processed aluminum influence crusher choice.

- Production Capacity: The crusher must meet the foundry’s production demands.

- Operational Costs: Maintenance and energy consumption are critical considerations.

Benefits of Using Crushers in Foundries

Using crushers in aluminum processing offers multiple benefits:

- Efficiency: Crushers streamline the preprocessing stage, reducing manual labor and time.

- Cost-Effectiveness: Efficient crushing reduces energy consumption and operational costs.

- Quality Control: Crushers ensure consistent output size, enhancing the quality of the final cast products.

- Environmental Impact: Efficient recycling of aluminum scrap minimizes waste and supports sustainability.

Conclusion

Crushers are indispensable tools in foundries for processing aluminum. The choice of crusher depends on various factors, including scrap size, desired output, and production capacity. By selecting the appropriate crusher, foundries can enhance efficiency, reduce costs, and improve the quality of their aluminum castings. Understanding the different types of crushers and their advantages and disadvantages is crucial for optimizing aluminum processing in foundries.