Since lime slaking is an integral part of treatment systems in water, wastewater, air pollution, and process industries, its performance will influence the overall effectiveness of the process as well as operation costs. This paper presents discussion and review of factors that affect efficiency and performance of lime slaking systems.

Equipment Used For the Slaking Process

Ball Mill Slakers

It is not the intent of this paper to evaluate the slaking equipment described below. The intent is to show the types of equipment available for slaking process. There are basically four types of lime slakers available on the market. They are:

- A. Slurry Detention Slakers

- B. Paste Slakers

- C. Ball Mill Slakers

- D. Batch Slakers

A slaker must mix the correct amount of quick lime(CaO)and water, hydrate the quicklime, and separate the impurities and grit from resultant calcium hydroxide slurry.

Ball Mill Slakers

Ball mill slakers are an adaptation of ball mills, which originally were designed for wet and dry grinding, to lime slaking. Two types of ball mills are used for slaking, horizontal and vertical. Ball mill slakers are generally used where:

the capacity required is too large for other types of slakers. due to zero discharge conditions at the site, no grit discharge is allowed. the water available is too high in sulfates or sulfites for regular slakers.

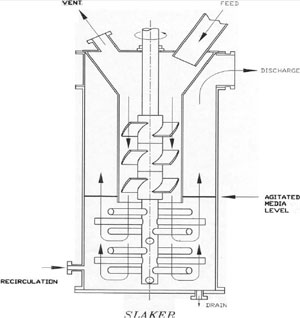

The ball mill slakers are much more expensive than paste or slurry slakers. They are available in sizes ranging from 1000lb/hr to 50 tons/hr. Figure 3 shows an attritor type vertical ball mill lime slaker.

The ball mill slakers are equipped with an external classifier, which separates slurry from the oversized grit and impurities. The oversize grit is recycled back into the mill for regrind.

Factors Affecting Slaking Process

The most important single factor that affects the process efficiency of a slaking system is the specific surface area of the particles of calcium hydroxide. The larger the specific surface area of the hydrate, the more surface is available for reaction, therefore, the more efficient the reaction and less consumption of lime. The specific surface of calcium hydroxide varies a great deal based upon the variables that are described below. The typical specific surface of calcium hydroxide ranges between 8, 000 to 58, 000 Cm 2 /gr. Empirical data shows that the relationship between the particle size of hydrate and specific surface, even though related, is not linear. Figure 8 shows 10 different limes and their hydrates’particle size and specific surface. These figures confirm a lack of direct correlation between particle size and specific surface.

Water Chemistry

Water chemistry is a major factor in the slaking process. Presence of certain chemicals in the slaking water will accelerate or hinder the slaking process. Water with high dissolved solids generally causes excessive foaming, which results in operational problems. Waters containing over 500Mg/l of sulfates or sulfites are unsuitable for slaking. This is true for paste and slurry-type lime slakers. Ball mill slakers, because of their ability to grind the particles of lime, are not affected as much by the presence of sulfates or sulfites in the slaking water.

The sulfates or sulfites cover the surface of the lime pebbles and will not allow water to penetrate the pores;therefore the slaking is greatly retarded. To slake under these conditions, the lime particles must be continuously abraded to expose new surfaces to water for slaking.

Figure 14 shows the effects of temperature rise versus time for water containing sulfates. Some chemicals have an accelerating effect on the slaking process. These are chlorides and sugars.