What type of crusher is needed to crush sillimanite

Time:12 September 2025

Sillimanite is an alumino-silicate mineral with a high degree of hardness and resistance to chemical weathering. It is commonly used in the manufacture of refractory materials and ceramics. Crushing sillimanite requires specific types of crushers that can handle its hardness and abrasiveness. This article explores the types of crushers suitable for processing sillimanite.

Properties of Sillimanite

Before selecting a crusher, it is essential to understand the properties of sillimanite:

- Hardness: Sillimanite has a Mohs hardness of approximately 6.5 to 7.

- Abrasiveness: Due to its hardness, sillimanite is abrasive and can cause significant wear on crushing equipment.

- Chemical Composition: It consists mainly of aluminum and silicon oxides.

Types of Crushers Suitable for Sillimanite

Several types of crushers can be used to crush sillimanite, each with its advantages and limitations. The choice of crusher depends on the specific requirements of the crushing process.

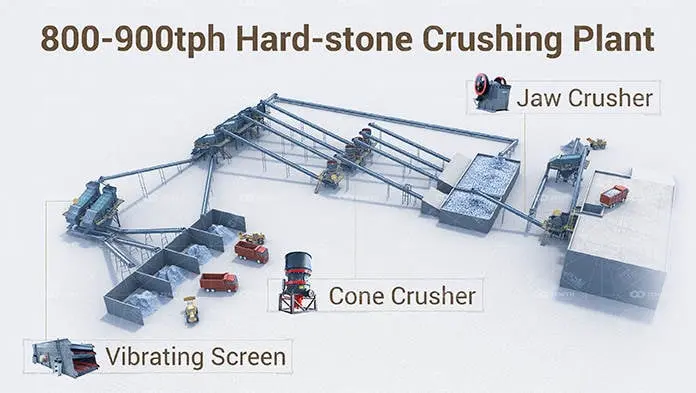

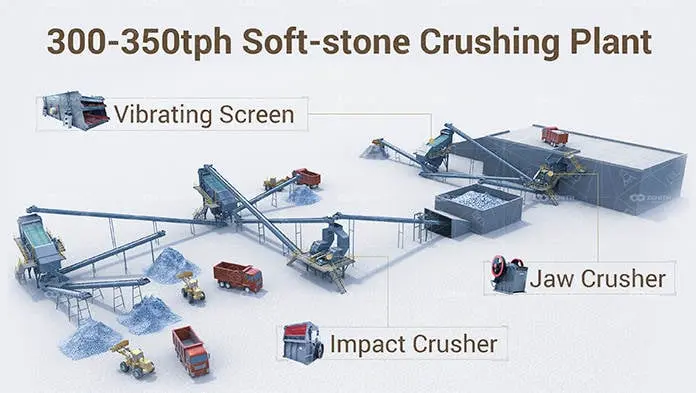

1. Jaw Crushers

Jaw crushers are commonly used for primary crushing of hard materials like sillimanite. They are suitable for:

- High hardness materials: Capable of crushing materials with high compressive strength.

- Large feed sizes: Ideal for processing large lumps of sillimanite.

Advantages:

- Simple structure and easy maintenance.

- High crushing ratio.

Limitations:

- May produce more fines than desired.

- Wear and tear on jaw plates due to abrasiveness.

2. Cone Crushers

Cone crushers are suitable for secondary crushing and can handle the hardness and abrasiveness of sillimanite effectively.

Advantages:

- High efficiency and uniform product size.

- Lower operational costs due to reduced wear.

Limitations:

- Requires precise feed control to avoid overloading.

- Higher initial investment compared to jaw crushers.

3. Impact Crushers

Impact crushers can be used for crushing sillimanite, especially when a finer product is required.

Advantages:

- Capable of producing fine and uniform particle sizes.

- Adjustable settings to control product size.

Limitations:

- Higher wear rates due to the impact mechanism.

- Not suitable for very hard materials unless specifically designed.

4. Hammer Mills

Hammer mills are another option for crushing sillimanite, particularly when processing smaller quantities.

Advantages:

- Simple design and easy operation.

- Can produce fine and uniform particle sizes.

Limitations:

- High wear rates on hammers and screens.

- Not suitable for large-scale operations.

Factors to Consider When Choosing a Crusher

When selecting a crusher for sillimanite, consider the following factors:

- Material Hardness: Ensure the crusher can handle the hardness of sillimanite.

- Feed Size: Choose a crusher that can accommodate the size of the sillimanite lumps.

- Desired Product Size: Determine the required product size and select a crusher that can achieve it.

- Capacity Requirements: Consider the volume of material to be processed and select a crusher with adequate capacity.

- Operational Costs: Evaluate the long-term costs, including wear parts and maintenance.

Conclusion

Selecting the right crusher for sillimanite involves understanding the material’s properties and the specific requirements of the crushing process. Jaw crushers and cone crushers are typically preferred for their ability to handle high hardness and abrasiveness, while impact crushers and hammer mills offer versatility for finer crushing needs. By considering factors such as material hardness, feed size, and operational costs, you can choose the most suitable crusher for your application.